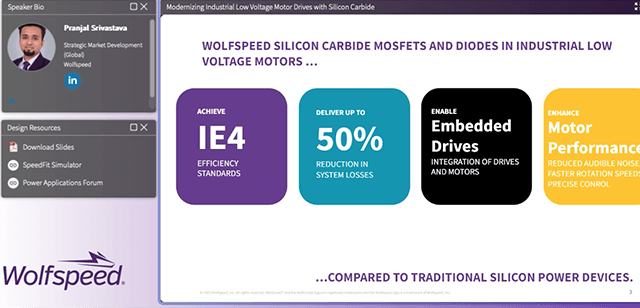

Wolfspeed silicon carbide enables embedded motor drives

Electric motors, including industrial low voltage drives, account for more than 50% of all electricity used in industry globally. Traditionally, industrial low voltage motor drives were designed with the motor and drive in separate housings and connected by a long cable, resulting in poor motor reliability or increased cost from needing output filters, wasted power and lower overall system efficiency.

Today silicon carbide is enabling a shift to embedded motor drives where the drive and motor are combined into one smaller unit. Combining motors and drives can reduce overall system cost by 20-40% and improve drive efficiency by up to 2.6% so motor manufacturers can achieve IE3 and IE4 efficiency standards.

Reach IE4 efficiency standards with Wolfspeed 650 V MOSFETS

Achieve IE4 efficiency standards with Wolfspeed’s 650 V MOSFETs. For example, in an 11 kW, 8 kHz system upgrading to a semi-bridgeless Totem Pole-PFC and replacing IGBTs in the inverter with drop-in silicon carbide MOSFETS yields:

- 2% efficiency improvement

- 220 W reduction in losses

- Meets IE4 efficiency standards.

Redesigning the PFC using a bridgeless totem pole topology and upgrading the inverter with silicon carbide MOSFETs improves efficiency even more to 2.4% while maintaining IE4 standards.

When compared to high-speed, soft-switched IGBTs, Wolfspeed 650 V MOSFETs offer drastically lower conduction losses and almost no switching losses, significantly improving the performance of embedded industrial motor drives.

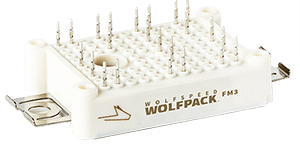

Reduce motor drive size while boosting efficiency at higher temperatures with WolfPACK™

Six-pack Wolfspeed WolfPACK™ power modules enable superior performance and system efficiency. When compared to leading IGBT solutions in a 25 kW inverter system, the WolfPACK™ achieves 1.1% higher efficiency with a 77% smaller heat sink (0.31 L vs 1.37 L).

Conversely, the WolfPACK can run at higher loads with smaller heat sinks, allowing designers to design embedded drive systems that are smaller and lighter and require up to 77% smaller heat sinks. Even at a higher 16 kHz switching frequency with the same heat sink, silicon carbide remains thermally stable and outperforms silicon IGBTs.

Quickly evaluate your designs with the NEW 25 kW FM3 Three-Phase Inverter

Designed to target industrial motor drives, Wolfspeed’s new 25 kW FM3 Three-Phase Inverter reference design provides comprehensive support to early SiC design-in activities. CRD25DA12N-FMC enables quick performance evaluation out of the box as a simple three-phase inverter topology. The flexibility of the generic power stage makes it simple to adapt to other applications, making it an ideal solution to evaluate or scale up power levels in industrial motor drives. This design features Wolfspeed’s 21 mW six-pack WolfPACK™ module with pre-applied TIM and achieves peak efficiencies over 99.5%, power density of 5.7 kW/L, and 30 Arms capable of up to 100 kHz switching frequency.

New Whitepaper & Webinar on Demand

Model silicon carbide efficiency with SpeedFit™

Maximize industrial low voltage motor drive efficiency when you simulate with SpeedFit Design Simulator, the first step to selecting the right devices for your design. Our online simulation tool offers an easy-to-use interface for evaluating Wolfspeed’s silicon carbide MOSFETs, diodes and power modules many power topologies. Start simulating today and harness the power of Wolfspeed silicon carbide in your industrial motor drives.

Wolfspeed Silicon Carbide Components for Industrial Low Voltage Motor Drives

Wolfspeed’s products represent the culmination of years of experience and expertise, where quality meets innovation to help bring your design forward.

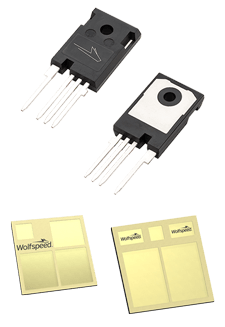

Discrete Silicon Carbide MOSFETs

Discrete Silicon Carbide MOSFETs

Discrete Silicon Carbide MOSFETs - Filter By

Discrete Silicon Carbide MOSFETs

Product SKU | Buy Online | Request Sample | Data Sheet | CAD Model | Blocking Voltage | RDS(ON) at 25°C | Generation | Current Rating | Gate Charge Total | Output Capacitance | Total Power Dissipation (PTOT) | Maximum Junction Temperature | Package | Recommended For New Design? | Qualification |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1200 V | 75 mΩ | Gen 3 | 32 A | 51 nC | 58 pF | 113.6 W | 150 °C | TO-247-4 | Yes | Industrial | |||||

1200 V | 75 mΩ | Gen 3 | 30 A | 51 nC | 58 pF | 113.6 W | 150 °C | TO-263-7 | Yes | Industrial | |||||

1200 V | 40 mΩ | Gen 3 | 64 A | 61 nC | 94 pF | 272 W | 150 °C | TO-263-7 | Yes | Industrial | |||||

650 V | 15 mΩ | Gen 3 | 120 A | 188 nC | 289 pF | 416 W | 175 °C | TO-247-4 | Yes | Industrial | |||||

650 V | 45 mΩ | Gen 3 | 47 A | 61 nC | 101 pF | 147 W | 175 °C | TO-263-7 | Yes | Industrial | |||||

650 V | 60 mΩ | Gen 3 | 36 A | 46 nC | 80 pF | 136 W | 175 °C | TO-263-7 | Yes | Industrial | |||||

1200 V | 32 mΩ | Gen 3 | 68 A | 111 nC | 133 pF | 277 W | 150 °C | TO-263-7 | Yes | Industrial |

Discrete Silicon Carbide Schottky Diodes

Discrete Silicon Carbide Schottky Diodes

Discrete Silicon Carbide Schottky Diodes - Filter By

Discrete Silicon Carbide Schottky Diodes

Product SKU | Buy Online | Request Sample | Data Sheet | CAD Model | Blocking Voltage | Current Rating | Generation | Forward Voltage(VF(type)) | Maximum Continuous Current (IF) | Total Capacitive Charge (QC (typ)) | Total Power Dissipation (PTOT) | Package | Qualification | Recommended For New Design? |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1200 V | 10 A | Gen 4 | 1.5 V | 10 A | 52 nC per leg | 170 W | TO-252-2 | Industrial | Yes | |||||

650 V | 16 A | Gen 3 | 1.5 V | 16 A | 44 nC | 150 W | TO-220-2 | Industrial | Yes | |||||

650 V | 16 A | Gen 6 | 1.27 V | 16 A | 29 nC | 100 W | TO-247-3 | Industrial | Yes |

Silicon Carbide Power Modules

Silicon Carbide Power Modules

Silicon Carbide Power Modules - Filter By

Silicon Carbide Power Modules

Product SKU | Buy Online | Request Sample | Data Sheet | CAD Model | Package | Configuration | Blocking Voltage | Current Rating | RDS(ON) at 25°C | Generation | Maximum Junction Temperature | Module Size | Recommended For New Design? | Qualification | View Product |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

FM3 | Six-pack (three-phase) | 1200 V | 30 A | 32 mΩ | Gen 3 MOS | 150 °C | 62.8 mm x 33.8 mm | Yes | Industrial |

Reference Designs

Reference Designs

Reference Designs - Filter By

Reference Designs

Product SKU | Name | Buy Online | Type | Topology | Power | Discrete/Module | Package | Device SKU(s) | Designed By | View Product |

|---|---|---|---|---|---|---|---|---|---|---|

CRD-22AD12N | 22 kW Bi-Directional Active Front End (AFE) | AC to DC | Three-Phase, 2-Level | 22kW | Discrete | TO-247-4 | Wolfspeed | |||

CRD25DA12N-FMC New | 25 kW FM3 Three-Phase Inverter | DC to AC | Three-Phase, 2-Level | 25kW | Module | FM3 | Wolfspeed |