Automotive

Wolfspeed’s Silicon Carbide semiconductors are putting EV systems designers in the driver’s seat.

Unlock A New Era of EV Efficiency with Wolfspeed Silicon Carbide.

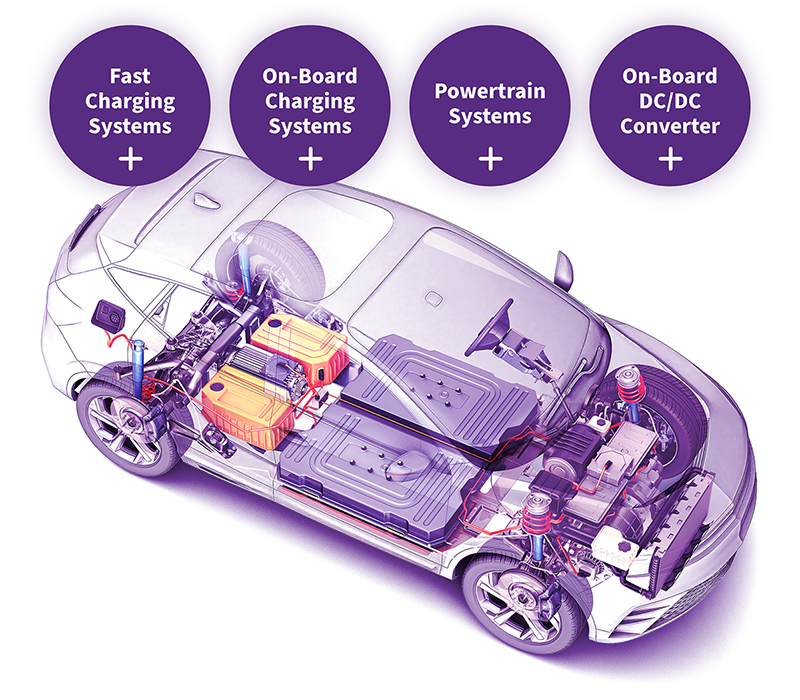

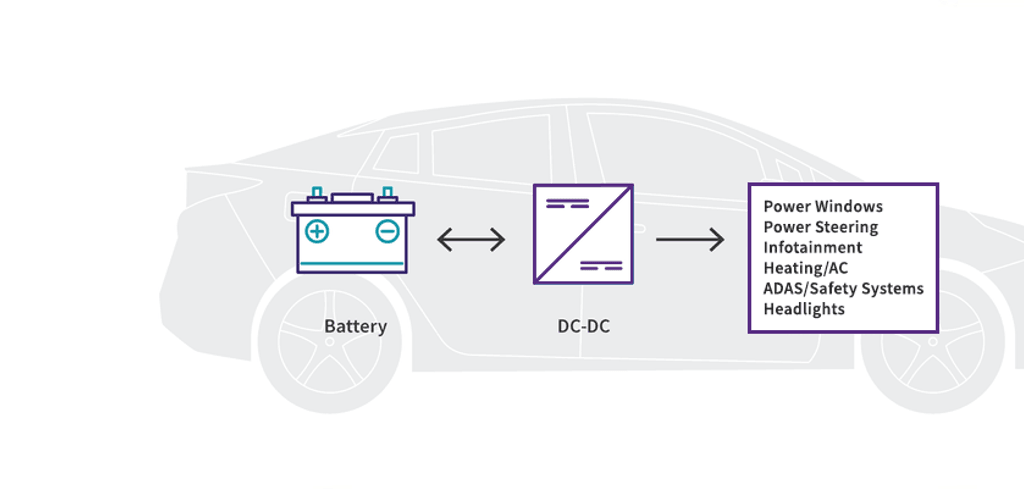

Silicon Carbide (SiC) technology can positively influence every major power path of an EV system. EVs utilizing Wolfspeed Silicon Carbide products have a lower overall system cost, and the ability to realize a more reliable operation in every section of the vehicle. Explore how Silicon Carbide is driving the EV revolution.

A Market in Motion

Wolfspeed launched the industry’s first Silicon Carbide (SiC) MOSFET in 2011 and has been leading the transformation from silicon to Silicon Carbide in EVs ever since. No longer constrained by the limitations of Si devices, EV designers embraced the faster switching speeds and greater power density that only Silicon Carbide MOSFETs and Schottky diodes enable, building smaller, lighter, and more efficient motors. Reducing power losses by nearly 80% also reduces consumers’ “range anxiety” by extending driving distance by up to 10%.

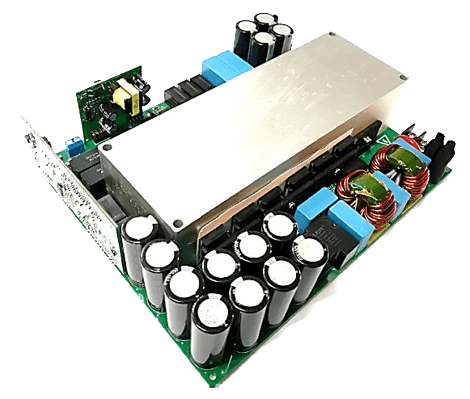

Wolfspeed offers the industry’s most comprehensive portfolio of high-performance, high-capability Silicon Carbide components, including our automotive-grade E-Series, a family of ruggedized devices which are the first commercially available Silicon Carbide MOSFETs and diodes to be AEC-Q101 automotive qualified and PPAP capable. The E-Series offers designers the highest available power density and can handle the harshest environments for both on-board and off-board automotive power conversion systems.

Automotive Applications