Industrial E-Mobility

The electrification of all vehicle types across land, sky, water, and railway.

Silicon carbide enables sustainable transportation

Innovations in Wolfspeed silicon carbide technology provide reliable, efficient, and cost-effective energy conversion and delivery.

Transportation accounts for approximately 20% of global carbon dioxide emissions, primarily due to the burning of diesel and gasoline within internal combustion engine (ICE) vehicles. To decarbonize transportation, industries are turning to the benefits of electrification: energy efficiency and zero emissions.

Wolfspeed uses the term ‘industrial e-mobility’ to describe the range of applications across land, sky, water, and railway industries that run on – or are now turning to – electric platforms powered by silicon carbide.

Reliable and efficient solutions from Wolfspeed

Industrial E-Mobility Applications

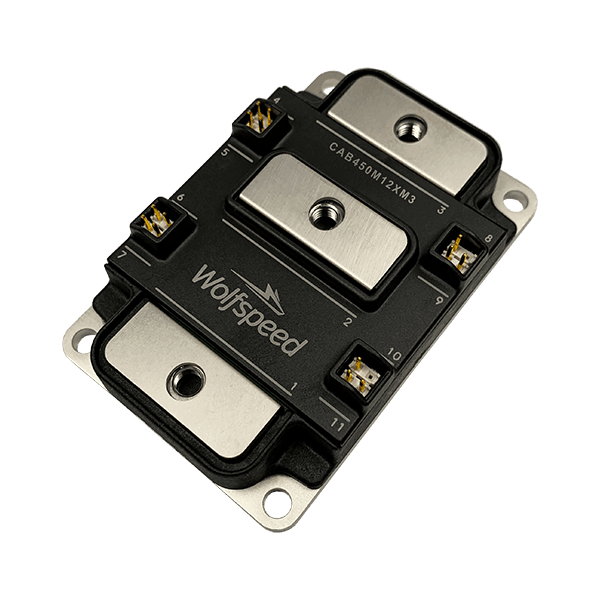

Industrial e-mobility applications require reliable and efficient solutions to manage high voltages and currents under demanding environmental conditions. Compared to silicon, silicon carbide devices enable higher switching frequencies and greater power densities at much higher operating temperatures – which are all necessary for high-power industrial e-mobility.

Sky

Electrified sky applications include electric vertical take-off and landing (eVTOL), electric short take-off and landing (eSTOL), electric conventional take-off and landing (eCTOL), hybrid electric aircraft (HEA), and more electric aircraft (MEA).

Where does silicon carbide fit within industrial e-mobility applications?

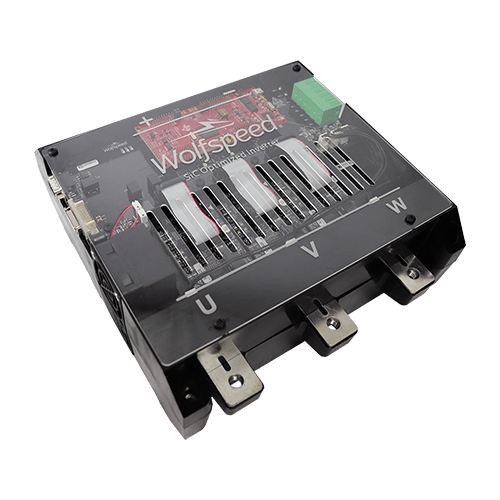

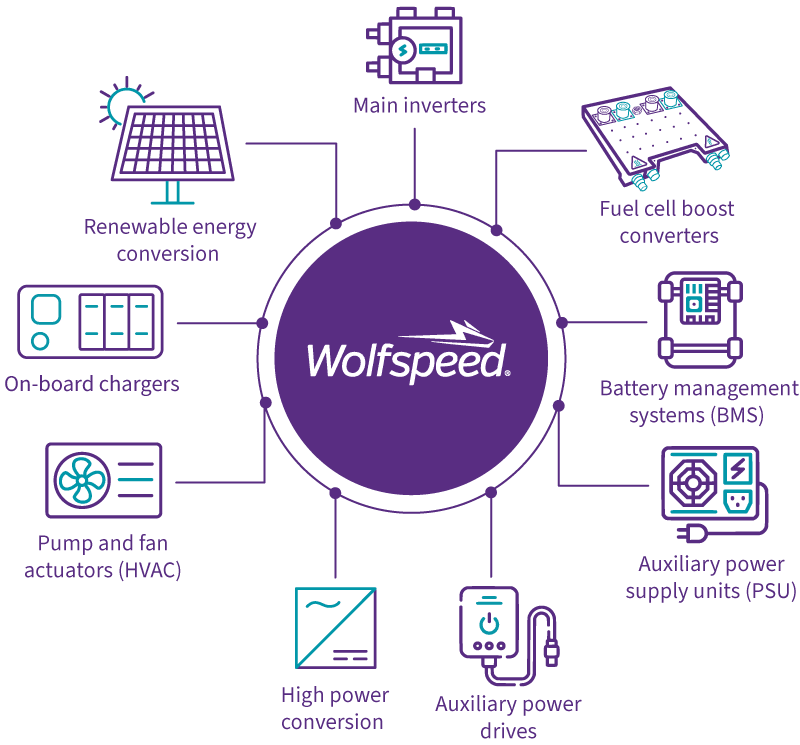

In addition to main inverters for battery electric vehicles (BEVs) and fuel cell boost converters for fuel cell electric vehicles (FCEVs), industrial e-mobility applications can also benefit from silicon carbide components within many different power electronics systems.

Each electrified system further reduces the number of mechanical components compared to ICE vehicles, enabling greater efficiency, lighter weight, and lower total cost of ownership (TCO). Overall, Wolfspeed silicon carbide enables higher power, lower switching losses, higher switching frequency, and system-level passive component reduction within these applications.

Industrial E-Mobility Power Systems

Systems with a break down voltage ranging from 650 V – 3300 V can benefit from Wolfspeed silicon carbide devices, including:

- Main inverters

- Fuel cell boost converters

- Battery management systems (BMS)

- Auxiliary power supply units (PSU)

- Auxiliary power drive

- Pump and fan actuators

- On-board chargers

- Renewable energy conversion

- High power conversion