Wolfspeed Unveils Cutting-Edge Silicon Carbide Module Solution to Boost Clean Energy Capacity

Innovative 2300V modules utilize 200mm silicon carbide technology to deliver energy efficiency for various applications, including renewable energy, energy storage, and high-capacity fast-charging infrastructure

Company announces partnership with EPC Power, a premier utility-scale inverter manufacturer

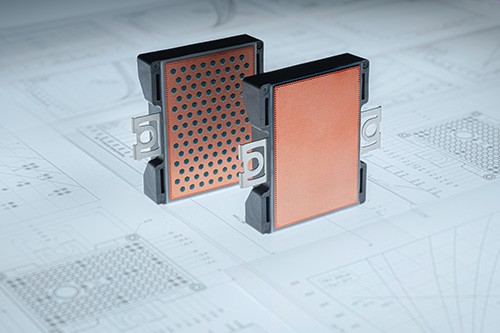

DURHAM, N.C., September 9, 2024 – Wolfspeed, Inc. (NYSE: WOLF), the global leader in silicon carbide technology, today unveiled a silicon carbide module designed to transform the renewable energy, energy storage, and high-capacity fast-charging sectors through improved efficiency, durability, reliability, and scalability. The 2300V baseplate-less silicon carbide power modules for 1500V DC Bus applications were developed and launched utilizing Wolfspeed’s state-of-the-art 200mm silicon carbide wafers.

Wolfspeed also announced today that it is partnering with EPC Power, a premier North American utility-scale inverter manufacturer. EPC Power will be employing the Wolfspeed® modules in utility-grade solar and energy storage systems, which offer a scalable high-power conversion system and high-performance controls and system redundancy.

“The solar and energy storage market remains among the fastest-growing segments of the renewable energy industry. As the pioneers of silicon carbide, we are driven to create solutions that will open the door to a new era of modern energy,” said Jay Cameron, Wolfspeed Senior Vice President and General Manager, Power. “Energy efficiency, reliability, and scalability are top of mind for our customers, such as EPC Power, who recognize the substantial advantages Wolfspeed’s silicon carbide brings to the table.”

“Silicon carbide devices open the door to a step-change in inverter performance and reliability. With our commitment to extreme reliability, performance, and security in our new ‘M’ inverter while also forging a deep commercial relationship with key suppliers, Wolfspeed was the obvious choice,” said Devin Dilley, President and Chief Product Officer, EPC Power.

With mounting global investment in renewable energy, the solar energy market is estimated to reach a $300 billion market capitalization by 2032.[1] According to the International Energy Agency (IEA), 2024-25 will see the highest energy demand growth rate since 2007, reinforcing the need for efficient and reliable clean power.[2] Wolfspeed’s silicon carbide solution helps bridge this crucial gap, supporting the next era of modern energy technologies while reinforcing U.S. clean energy manufacturing leadership.

Cameron continued, “This platform further validates our investments in 200mm wafer technology and production as the potential of silicon carbide continues to be recognized by industry leaders across all mission-critical applications.”

Click here to learn more about Wolfspeed’s partnership with EPC Power.

Industry Leading Switching Performance

Wolfspeed's 2300V modules will improve system efficiency, while reducing the number of passive components. They offer 15% greater voltage headroom compared to similar silicon carbide modules, improved dynamic performance with consistent temperature stability, and a substantial reduction in EMI filter size. Wolfspeed’s technology achieves a 77% reduction in switching losses over IGBTs and a 2-3x reduction in switching losses for silicon carbide devices intended for 1500V applications.

Market Scalability Through Design Simplification

2300V silicon carbide modules will allow system designers to leverage lower cost printed circuit boards to cut manufacturing costs and significantly reduce development time compared to legacy bus bar solutions.Furthermore, Wolfspeed’s 2300V modules will enable the industry to adopt the two-level topology, resulting in simplified system design and reduced driver count compared to IGBT-based three-level configurations. The benefits of 2300V modules support a building block approach to easily scale power tenfold, from kilowatts to megawatts.

Prolonged System Lifetimes & Durability

Wolfspeed’s 2300V silicon carbide modules will allow customers to further enhance the lifetime and durability of their systems. This is achieved through an optimized Failure in Time rate for continuous 1500V DC operation and improved cosmic ray susceptibility compared to a 2000V design. When used in a two-level implementation, 2300V modules reduce the amount of potential single points of failure across the system.

Visit our website for additional information about technical specifications of Wolfspeed’s pioneering 2300V module technology.

About Wolfspeed, Inc.

Wolfspeed (NYSE: WOLF) leads the market in the worldwide adoption of silicon carbide technologies that power the world’s most disruptive innovations. As the pioneers of silicon carbide, and creators of the most advanced semiconductor technology on earth, we are committed to powering a better world for everyone. Through silicon carbide material, power modules, discrete power devices and power die products targeted for various applications, we will bring you The Power to Make It Real™. Learn more at www.wolfspeed.com.

X (formerly Twitter): @Wolfspeed

LinkedIn: @Wolfspeed

Forward Looking Statements:

This press release contains forward-looking statements by Wolfspeed involving risks and uncertainties, both known and unknown, that may cause Wolfspeed’s actual results to differ materially from those indicated. Actual results may differ materially due to a number of factors, including the risk we may be unable to manufacture these new products with sufficiently low cost to offer them at competitive prices or with acceptable margins; the risk we may encounter delays or other difficulties in ramping up production of our new products; customer acceptance of our new products; the rapid development of new technology and competing products that may impair demand or render Wolfspeed’s products obsolete; and other factors discussed in Wolfspeed’s filings with the Securities and Exchange Commission, including its report on Form 10-K for the year ended June 30, 2024, and subsequent filings. For additional product and company information, please refer to www.wolfspeed.com.

Wolfspeed® is a registered trademark and The Power to Make It Real™ is a trademark of Wolfspeed, Inc.

Media Relations:

Bridget Johnson

Head of Corporate Marketing and Communications

847-269-2970

media@wolfspeed.com

Investor Relations:

Tyler Gronbach

VP, External Affairs

919-407-4820

investorrelations@wolfspeed.com