Keeping the Lights on with Wolfspeed SiC

By Sarah Magargee

Article

EPC flips the switch on modular, reliable grid-scale energy storage

For decades the power grid has served as a reliable conduit for electricity between power producers and consumers, seamlessly delivering electricity with the flip of a switch. Increasing demand for electricity created from renewable sources, including solar and wind, creates new challenges for the existing power grid including integrating energy storage to ensure sufficient electricity during peak use times.

EPC Power, a premier utility-scale inverter manufacturer offering cutting edge power conversion solutions, has partnered with Wolfspeed to create a solution to the energy storage challenge. Utilizing the power of silicon carbide, “M” is the industry’s first utility-scale string-style inverter that makes grid-tied energy storage more efficient, reliable, and scalable than ever before.

- Create an energy storage inverter with industry-leading efficiency and power density

- Design a modular system that addresses a wide range of power and voltage levels with a single inverter building block

- Ensure system is low maintenance, easily serviced and mass produceable for rapid global deployment

- Partnership between two innovative companies to design the 2300 V Wolfspeed WolfPACK™ power module into EPC Power’s novel energy storage solution

- “M” Inverter – the industry’s first modular string-style central inverter optimized for battery-based energy storage systems

- Grid-ready flexible inverter covering a wide range of power and voltage levels delivering industry-leading efficiency and power density

- Low maintenance and service needs

- Easily mass produced to rapidly deploy a solution on a global scale

‘M’ is for Modularity

Traditional energy storage systems use central inverters in power conversion. These monolithic devices operate at 4-6 megawatts and are prone to downtime due to the system size and complexity. Central inverters are further taxed when storing significant loads of renewable energy for extended periods of time. EPC’s “M” inverter combines the flexibility of string-style inverters typically seen in residential and commercial solar systems, with the scale necessary to power entire cities with renewable energy.

Using a modular approach “M” enables customized central-style inverters by connecting multiple small inverters. “M” inverters are significantly smaller with fewer passive components, have a wide AC and DC operating range and offer world-class power density. The “M” modular system is easier to install and maintain than central inverters and delivers superior up-time with fewer points of failure.

“M" bridges the gap between two inverter architectures creating stable and reliable battery storage at a significantly higher voltage level. By breaking energy into smaller blocks, power companies can design inverter systems to better match specific needs at specific energy storage sites.

The Key to Innovation

“Technology unlocks business opportunity. Silicon carbide is a tool and if you can glean the benefits from it in the system you can make a paradigm shift in technology. Wolfspeed SiC is enabling EPC to make a paradigm shift in how energy is created and stored globally.”

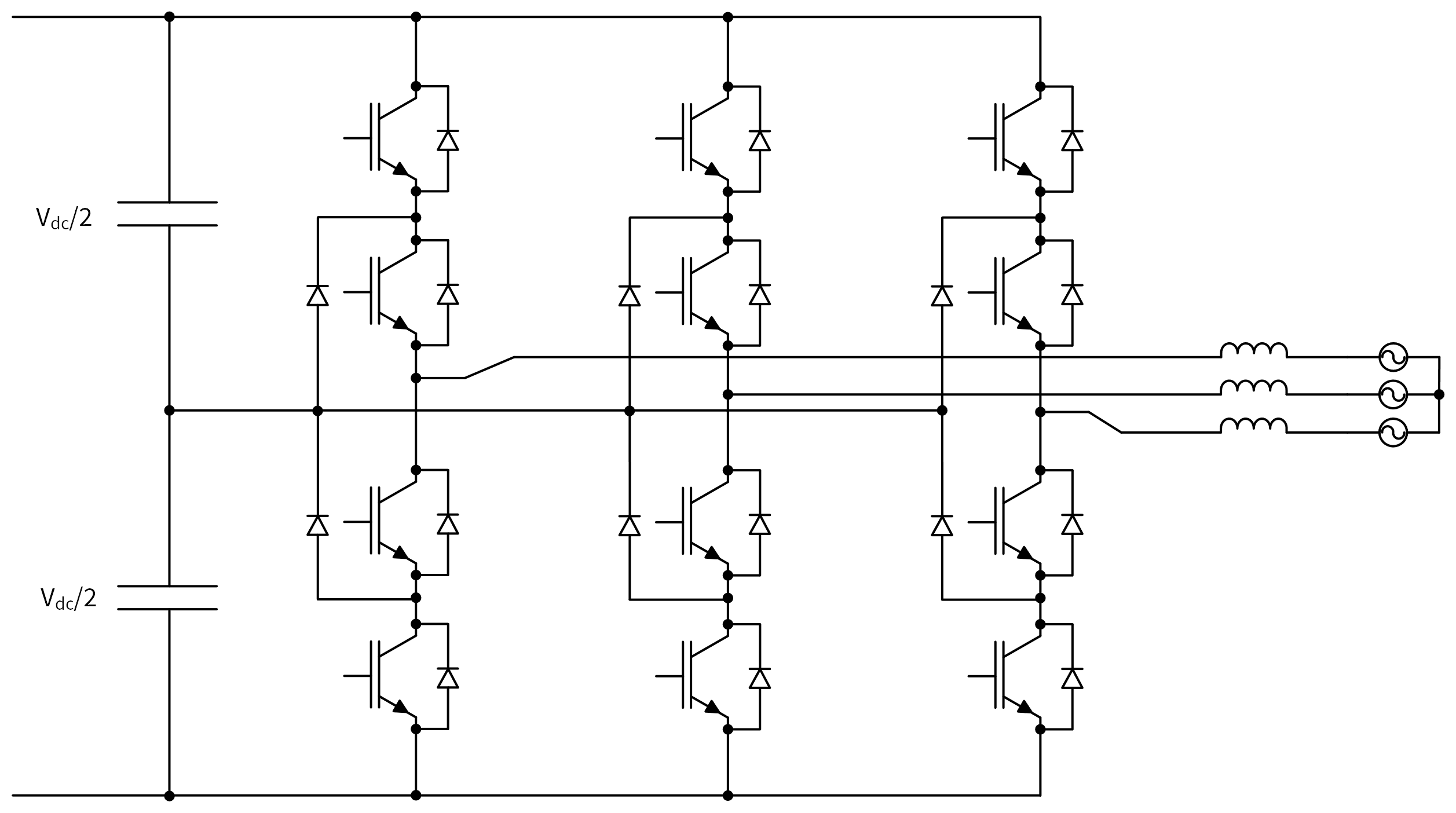

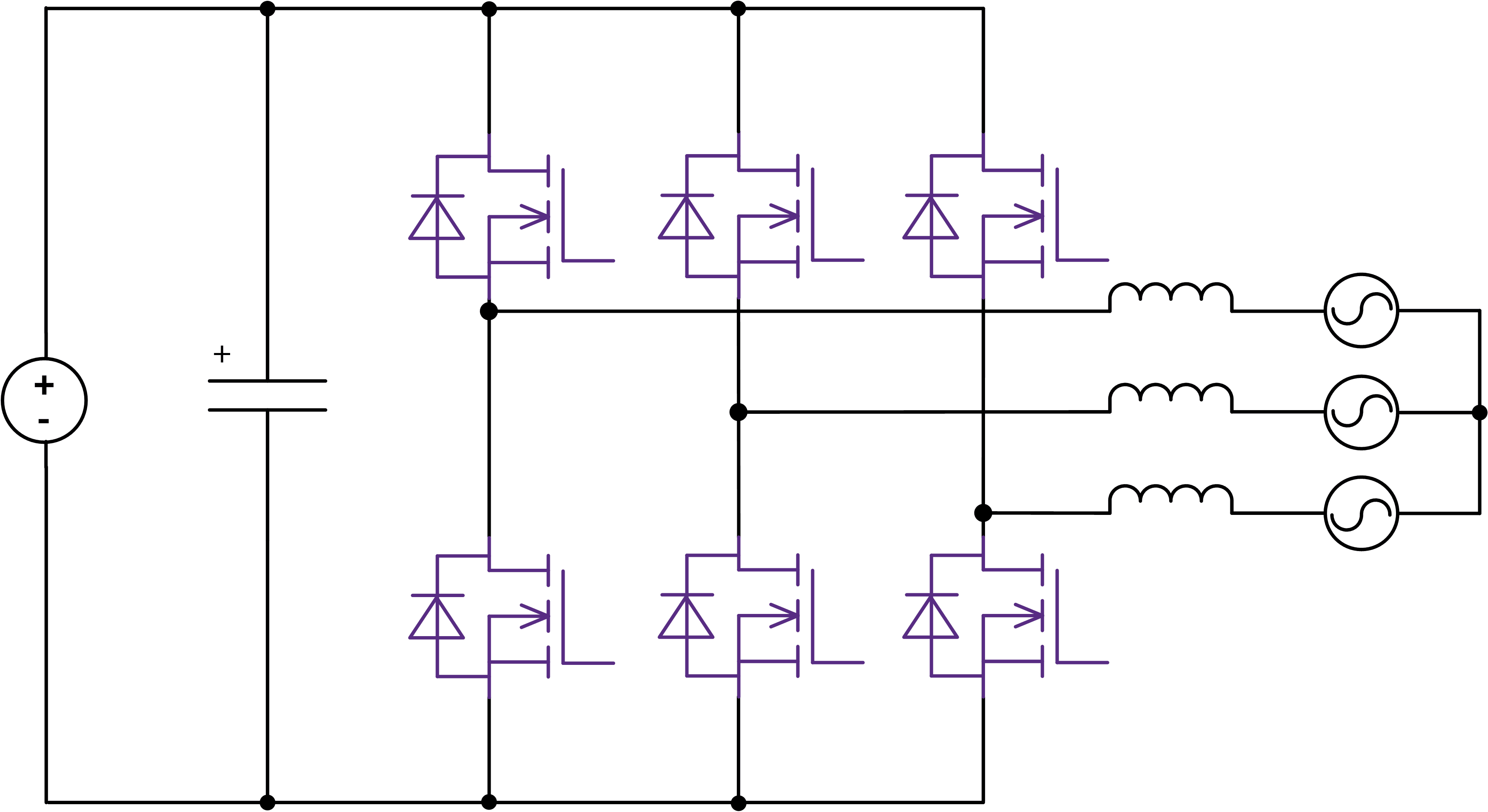

EPC knew leveraging the unique benefits of silicon carbide was key to unlocking reliable energy storage at the grid-level. Wolfspeed’s new 2300 V silicon carbide Wolfspeed WolfPACKTM power module was designed specifically for 1500 V bus applications and enabled the shift from a typical three-level architecture to a simplified 2-level power conversion system. This solution significantly cut development time and cost by moving the system design from a legacy bus bar to lower cost PCBs.

Figure 1 compares a complex 3-level NPC system architecture that utilizes 1200 V IGBTs to the drastically simplified 2-level system utilizing the 2300 V WolfPACK power module.

The simpler 2-level system has a reduced driver count and control complexity, along with improved scalability.

SiC module’s switching performance enabled EPC to dramatically scale down the size of “M,” reducing the number of passive components and overall system cost. This innovation makes installation and maintenance easier creating the industry’s first inverter optimized for utility-scale battery energy storage.

EPC worked closely with Wolfspeed experts to prolong the "M" system's lifetime by maximizing the 2.3 kV WolfPACK's 7-8x reduction in cosmic ray FIT compared to a similar 2 kV device. Capitalizing on this feature enables M’s longer lifetime and higher reliability which directly translates to less field failures and lower maintenance costs.

The Power of Partnership

As the creator of the world’s most advanced silicon carbide semiconductor technology, Wolfspeed provides hands-on support throughout the design process to help customers maximize the benefits of silicon carbide. This philosophy guides Wolfspeed’s partnerships with innovators in the marketplace and enables the world’s most disruptive technologies.

“EPC and Wolfspeed’s philosophies align so well. How can you not partner with the company that pioneered the commercialization of silicon carbide and is years ahead of the competition?”

“Wolfspeed and EPC came to the table, rolled up their sleeves and got to work,” said Jay Cameron, Vice President and General Manager for Wolfspeed Power. “I am impressed with EPC’s level of ambition and capability, pushing all of us to move efficiently toward the launch of products that revolutionize the grid and provide a more sustainable future for us all.”

About EPC

EPC Power is a leading provider of power conversion solutions, specializing in utility-grade solar and storage inverters. With a commitment to innovation, quality, and customer satisfaction, EPC Power delivers reliable and scalable solutions to meet the evolving needs of its customers. For more information, visit www.epcpower.com.