Reimagine Auxiliary Power Supply System Durability & Cost with Wolfspeed’s New 1700 V MOSFET Technology

Article

Low-power auxiliary power supplies are found in nearly all motor drives, EVs, fast chargers, and renewable energy systems. While these power supplies often receive less attention than the main power stage, they are still a crucial part of making the system operate effectively. Designers are constantly faced with the often-conflicting challenges of improving cost, reliability and size of the system – while minimizing risk and supporting multi-sourcing.

Wolfspeed's latest industrial C3M0900170x and automotive-qualified (AEC-Q101) E3M0900170x SiC MOSFET product families enhance the design capabilities of auxiliary power supplies in the 20 to 200 W range. These power supplies are vital in rapidly growing markets such as renewable energy, industrial motor control, and vehicle electrification. Built on Wolfspeed's reliable 3rd generation SiC technology and exclusively manufactured in their industry-leading 200mm fabrication facility, this product family allows engineers to reconsider how to address low-power auxiliary power supply system tradeoffs.

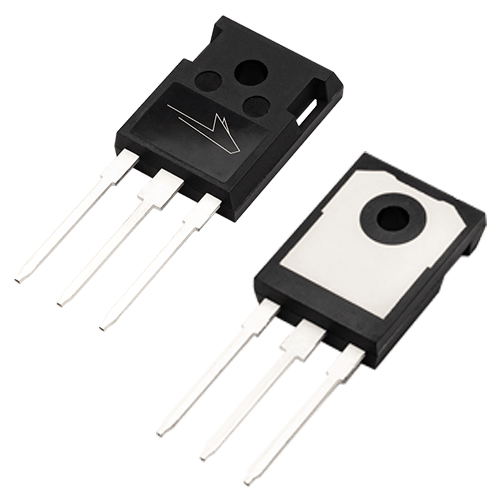

TO-247-3

C/E3M0900170D

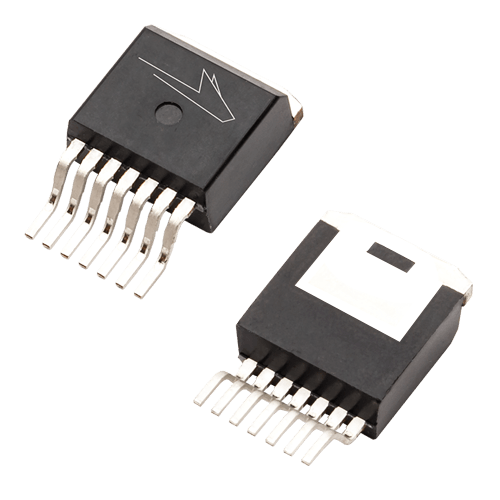

TO-263-7L

C/E3M0900170J

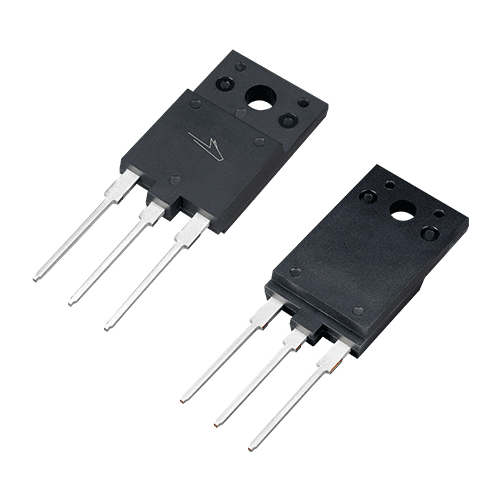

TO-3PF

C3M0900170M

In addition to the TO-247-3 (D) and TO-263-7 (J) packages in Wolfspeed’s portfolio, a new fully molded package – the TO-3PF (M) – has been added to support industrial applications. This package reduces assembly cost and errors by eliminating the need for an isolated thermal interface material. The TO-3PF (M) package also improves robustness in harsh environments by increasing the minimum creepage between pins to 4.85mm, with the exposed drain pad eliminated.

Improved Performance & Drop-In Capability

Wolfspeed’s C3M and E3M SiC MOSFET technology provides multiple improvements over the previous C2M 1700V family and competitor devices. Gate charge has been cut from 22nC in the C2M equivalent device to just 10nC in the new C3M / E3M family - reducing the gate power requirements and simplifying the startup operation in a flyback power supply. Furthermore, the output capacitance has been reduced - resulting in 30% lower Eoss to reduce switching losses.

Realizing system level improvements isn’t always easy, as design changes can be time and resource intensive. Wolfspeed’s new family of 900mΩ SiC MOSFETs offers drop-in compatibility in most existing low-power auxiliary power supply designs allowing you to take advantage of the new devices without extensive redesign. From a package standpoint, the through-hole TO-247-3 and surface mount TO-263-7 are compatible with other SiC and Silicon devices on the market today, requiring no changes to PCB layout or heatsink attachment.

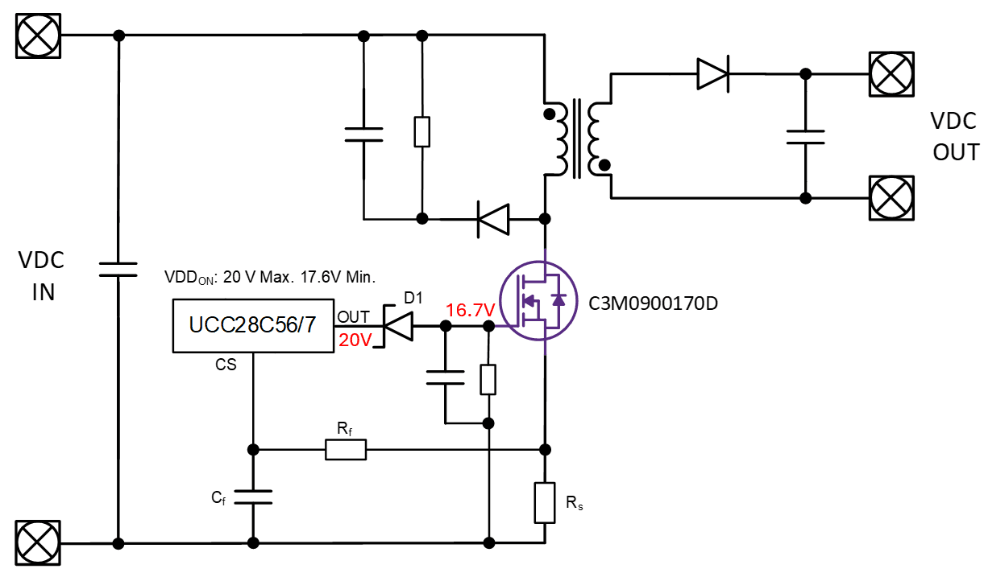

Many auxiliary power supplies have a 12-15V output used for running other controls or loads. The C3M/E3M family can directly utilize this voltage rail for the flyback controller and resulting gate voltage - eliminating the need to have a separate auxiliary winding or transformer tap to deliver the higher 18-20V required by previous generations and some competitor devices.

The gate voltage levels of competitive Si and SiC MOSFETs range from 12V to 20V - making multi-sourcing more challenging for designers. Fortunately, Wolfspeed’s C3M0900170x family supports 12-18VGS directly. Due to the optimally tuned internal gate resistance, the Wolfspeed components work in circuits with up to 22VGS. In designs with gate voltages >18V, the external gate resistor can be replaced with a Zener diode to reduce the driving voltage to within the 12-18V range.

Replacing RG_EXT with a 3.3V Zener diode to reduce VGS at the MOSFET gate

Performance Improvements when Upgrading Silicon-Based Systems

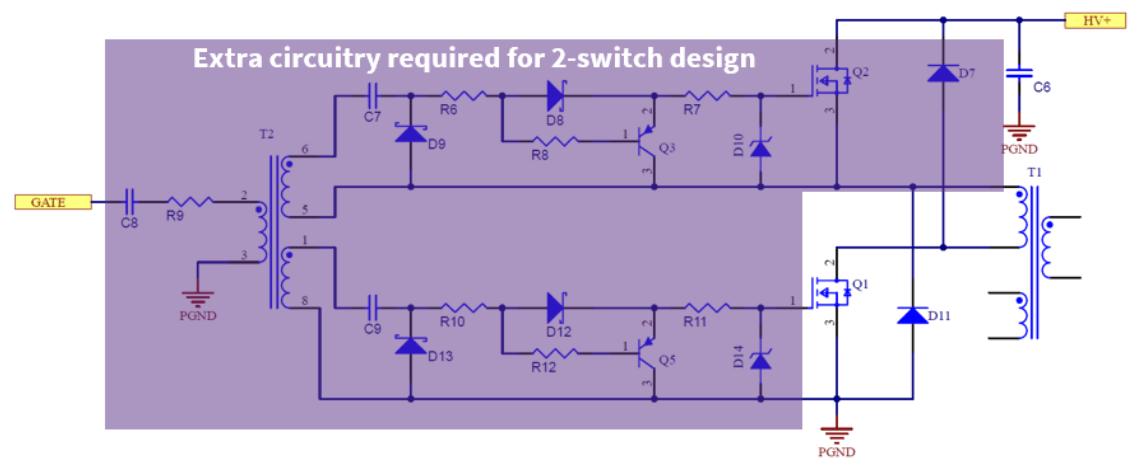

High voltage (1500-2000 V) silicon MOSFETs can be used in this system space; the drawback is that the 1-2 Ω devices tend to be expensive, due to high RDS(ON) per unit area, and have high losses. Instead, a 2-switch flyback topology can be utilized to enable selection of lower voltage silicon devices. Though the devices are less expensive, the 2-switch topology is more complicated to design - requiring more components and space.

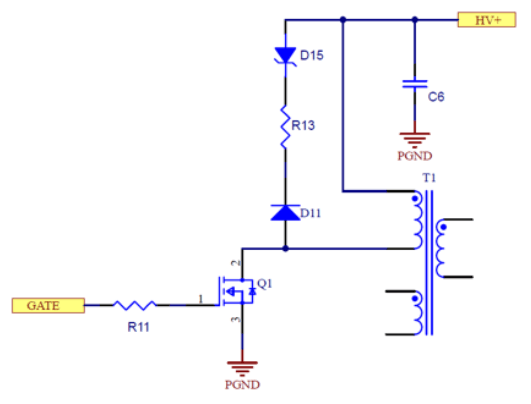

Silicon Carbide MOSFETs are ideally suited to these voltage levels and can easily achieve a low RDS(ON) and low switching losses for auxiliary power supply applications. Enabling the designer to utilize a single-switch flyback topology, which eliminates extra circuitry and design complexity required for a 2-switch design.

2-switch topology requires additional components and PCB area

A simplified single-switch design using a SiC MOSFET saves space and cost.

Durability is Designed-In for All Applications

Auxiliary power supplies are found in many industrial and automotive applications requiring long life and reliable operation. The C3M/E3M family is rated for -55 to +175 °C junction temperature operation making it suitable for extreme temperature conditions. The C3M0900170D, C3M0900170J, and E3M0900170D pass THB-80 (HV-H3TRB) testing, where the device is subjected to 1360V blocking voltage in 85% humidity and 85 °C ambient for 1000 hours.

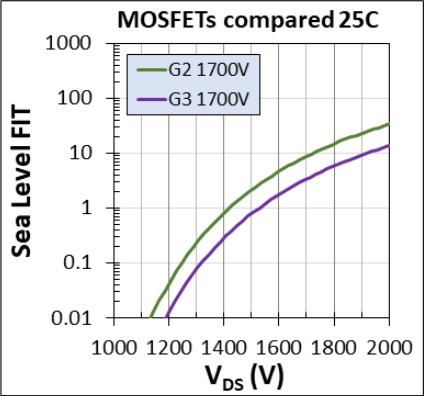

When discussing semiconductor ruggedness across diverse applications, cosmic radiation FIT (failures in time) rate must be considered. Wolfspeed’s C3M / E3M family further reduces the already low FIT rate of the legacy C2M family, through improved device design and chip size reduction. A typical 1200V bus flyback utilizing Wolfspeed Gen 3 devices has a 65% reduction in FIT rate after 10 years of continuous operation at sea level when compared to the previous generation.

Design Resources to Kickstart Your SiC System Development

Wolfspeed is a leader in the industry when it comes to supporting engineers with their designs - and the new 1700V family of parts is no exception. Check out the resources below to accelerate your design using this new C3M / E3M family of 900mΩ 1700V devices.

- CRD-020DD17P-J Reference Design: 20W 60-1000V input reference design with full design files available for download.

- KIT-CRD-025DD17P-J Evaluation Board: 25W 60-1000V input evaluation board with design files. This evaluation board utilizes a similar circuit to the reference design above but has an easier layout for testing and prototyping in the lab. These will be available for purchase in Q2 2025.

- Device Models: PLECS and Spice models are available for download to help with simulation work prior to testing.

- Product Samples: Request samples on our website to get started on your design or drop them into your existing product to evaluate the performance.

- Power Applications Forum: Join our technical community and ask our SiC experts about any questions or challenges you are facing in your design.