Revolutionizing Power Electronics with Silicon Carbide to Pioneer Sustainable Solutions

Article

*Copyright note: This content was originally published on IEEE Explore.

© 2025 IEEE. Personal use of this material is permitted. Permission from IEEE must be obtained for all other uses, in any current or future media, including reprinting/republishing this material for advertising or promotional purposes, creating new collective works, for resale or redistribution to servers or lists, or reuse of any copyrighted component of this work in other works

Abstract— The power semiconductor industry is driven by the increasing demand for efficient, clean and sustainable energy solutions which requires increased attention on advanced materials. Among these, silicon carbide (SiC) has emerged as a disruptive technology providing tangible benefits over traditional silicon-based devices.

SiC offers a combination of unique properties, such as high thermal conductivity and high breakdown electric field and bandgap, making it ideal for high-power and high-frequency applications that require greater efficiencies. In this paper, we will explore SiC's impact across various applications - from vehicles and renewable energy systems to industrial supplies - to highlight its pivotal role in revolutionizing electronics.

Commercial adoption of SiC technology requires continuous attention to material defects, device reliability and related packaging technologies. In this paper, we also aim to provide researchers and professionals practical knowledge on how SiC can bring highly efficient and dependable solutions to the power semiconductor industry.

I. Introduction

Power electronics are embedded in nearly every aspect of our lives. The evolution of power electronics has been closely tied to technological advancements in materials science, semiconductor device technology, and system design. The invention of semiconductor materials opened a new era of unprecedented progress in electronic devices. With advancements in silicon materials and devices, semiconductor technologies became scalable and adaptable, and the power electronics field became a dynamic and integral part of all electronic systems. The development of wide-bandgap semiconductor technologies such as SiC and gallium nitride (GaN) have opened new horizons, offering higher efficiency, greater power density, and the ability to operate at higher temperatures and voltages, pushing the upper envelope of power electronics systems. These newly expanded energy capabilities enable the conversion of energy from one form to another with minimal losses, while increasing the functionality and reliability of systems to expand power electronics into critical areas such as renewable energy systems, electric vehicles and smart grids.

II. Major Semiconductor Changes Don’t Happen Very Often

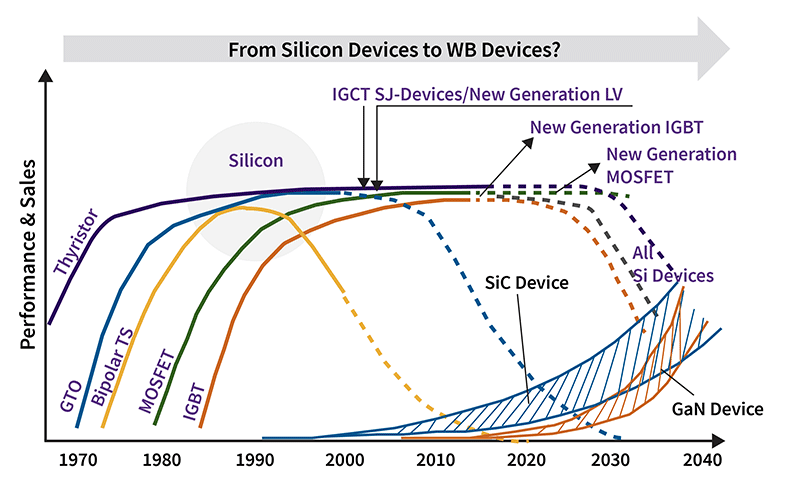

As demonstrated in Fig. 1, silicon enabled the creation of semiconductor devices such as thyristors and transistors during the mid 1900s. These devices made the handling of voltage and current possible with reliable switching capabilities; however, they were limited by slower switching speeds and inefficient control. As silicon technology advanced, metal–oxide–semiconductor field-effect transistor (MOSFET) and insulated-gate bipolar transistor (IGBT) device technologies became commercialized, providing enhanced electrical characteristics. MOSFETs, introduced in 1979, provided faster switching and higher frequency operation, ideal for low- to medium-voltage applications. IGBTs, introduced in 1985, combined the advantages of both MOSFETs and bipolar transistors, offering higher voltage capabilities with faster switching and greater efficiency, catalyzing considerable progress in power electronics systems and allowing the development of advanced circuit topologies and control methodologies.

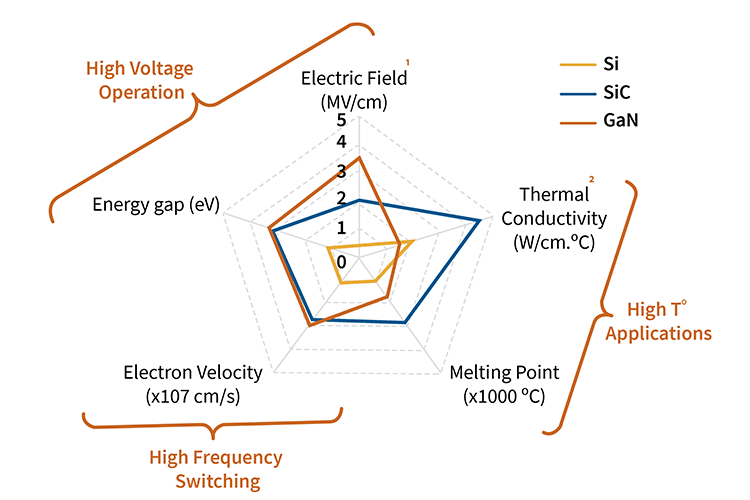

These technological advancements set up clear figures of merit, driving future developments in the field including energy efficiency, power density and reliability, pushing silicon beyond its limits. This resulted in increased efforts in wide-bandgap semiconductor materials research. As reflected in the radar chart in Fig. 2, SiC has a three times wider band gap and ten times higher breakdown electric field compared to silicon, and thus has emerged as an ideal material for next generation power devices.

Wolfspeed launched the industry’s first SiC MOSFET in 2011 and has been leading the transformation from silicon to SiC ever since, opening new horizons for power converter technologies that are evident in the variety of applications that are covered in this paper.

III. The Sustainable Future

Power electronics serve as the fundamental technology for the efficient conversion, regulation, and control of electrical energy. Innovations within this field are crucial to the deployment of sustainable energy solutions across a range of sectors, including renewable energy generation, electric mobility, and industrial automation.

A. Electric Vehicles (EVs)

EVs represent a critical part in the transition to a sustainable future, as they have the potential to significantly reduce greenhouse gas emissions, improve urban air quality, and reduce reliance on non-renewable fossil fuel resources. Power electronics in EVs manage and control the flow of power between the battery, motor, and auxiliary systems through key components like inverters, converters, and motor controllers. These systems enable functions such as converting direct current (DC) from the battery to alternating current (AC) for the motor, regulating voltage levels for various vehicle systems, managing battery charging and discharging, and enabling regenerative breaking to recapture energy. As SiC materials and device technologies mature, it’s now possible to develop reliable, rugged power systems into EVs without sacrificing efficiency or sustainability. According to a recent report published by McKinsey, by 2027, over 50% of battery EVs could rely on SiC powertrains, compared with about 30% today [2].

A.1. Powertrain Systems

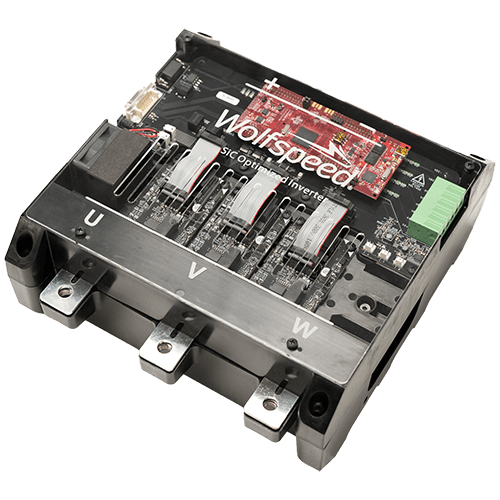

The biggest and most mission-critical system, responsible for getting the EV from point A to point B is the powertrain. An EV’s powertrain handles taking energy stored in the vehicle’s battery system and supplying it to the wheels. The amount of power that it takes to move a fully loaded vehicle is enormous, and delivery needs to be instantaneous and predictable. Furthermore, the vehicle's range is most dictated by the ability to provide power with maximum efficiency and minimum resistance. The continued evolution of the SiC MOSFET has made it possible for engineers to design powertrain inverters rugged enough to handle high-temperatures and extreme humidity, while providing higher voltage ranges and faster switching speeds compared to their Si counterparts. Utilizing SiC MOSFETs in the EV powertrain can reduce power losses by up to 80%, which extends driving distance by up to 10%. In addition to the improved efficiency benefits to the daily driver, a SiC MOSFET's efficiency also enables automotive system designers the opportunity to offer powerful performance with smaller, lighter, and more efficient motors than traditional designs. One example of a SiC-based inverter is Wolfspeed’s 80 kHZ, three-phase reference design (Fig. 3). This design achieves two times greater power density than comparable silicon-based inverters and is embedded in an ultra-low inductance footprint.

A.2. Fast Charging Systems

The global transition to EVs necessitates considerable advancements in charging infrastructure to meet the demands of widespread deployment. While low-power on-board chargers (<15 kW) are adequate for residential charging during idle periods, and SiC switches have better reverse polarity operation than silicon, making them ideal for bi-directional charging, extended travel and commercial applications require significantly reduced charging times to approach the refueling speed of conventional gasoline stations. Achieving these faster charge times will depend on concurrent progress in battery technology and the development of a robust, high-power charging infrastructure capable of supporting rapid energy transfer. SiC enables superior switching speed and higher power delivery delivering much more efficient fast charging. These factors have bolstered SiC MOSFET and module proliferation in EV charging profiles, and mid-voltage technologies are being introduced to meet the needs of mega-watt fast charging systems that are needed for long-haul electrified trucks and delivery vehicles.

A.3. On-Board Charging Systems

On-board battery chargers are the key to keeping EVs powered: they take AC current from the car owner’s home and convert it to DC power to recharge the battery. They are also often capable of regenerative breaking, harvesting kinetic energy from the vehicle itself to provide added charge when braking. SiC device technologies make these systems efficient in their output, size and speed. When designed with bi-directional energy-transferring capabilities, SiC based on-board charging systems can both receive energy from the grid and give it back, helping to stabilize the electrical grid of the future, or even power an owner’s critical home systems during a power outage.

A.4. On Board DC/DC converter

The on-board DC/DC converter plays a critical role in modern vehicles, particularly in EVs, where power demands are elevated due to the integration of advanced systems such as infotainment, navigation, lighting, and autonomous controls. This converter handles converting and regulating DC power from the battery to provide the correct voltage for a wide range of interdependent systems, ensuring real-time performance to prevent failures that could disrupt vehicle operation. Advances in SiC technology are revolutionizing the efficiency and performance of these DC/DC converters. SiC devices offer superior electrical and thermal properties compared to traditional silicon components. They run with higher efficiency by reducing switching and conduction losses, which not only improves energy conversion but also minimizes heat generation. SiC’s ability to function at higher temperatures and faster switching speeds enhances the real-time voltage regulation of complex vehicle systems. Additionally, these advancements allow for smaller, lighter power converters, which reduce overall vehicle weight and free up space for other components.

B. Renewable Energy

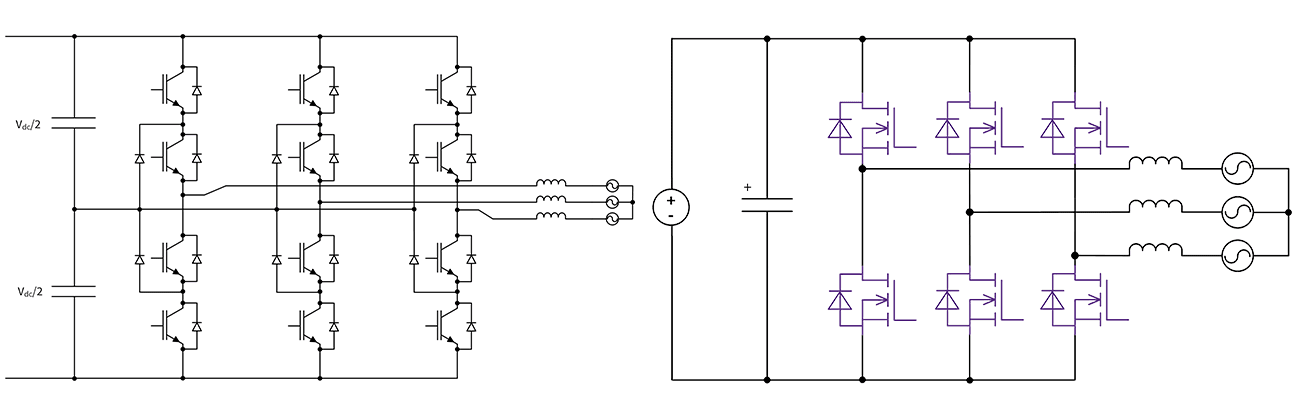

Renewable energy is the fastest-growing energy source globally, accounting for one-third of global power generation capacity, with SiC technology playing a pivotal role in enhancing the efficiency and power density of next-generation energy storage, solar, and wind systems. According to the International Energy Agency (IEA), global renewable capacity additions increased by nearly 50% in 2023, marking the fastest growth in two decades, and projections suggest that nearly 3,700 gigawatts of new capacity will be added between 2023 and 2028 [3]. This expansion is primarily driven by solar photovoltaics (PV) and wind energy, which are expected to account for 95% of the increase due to their cost advantages over both fossil and non-fossil fuel alternatives. By 2028, renewables are projected to account for over 42% of global electricity generation, with wind and solar PV contributing 25%. Achieving a higher return on investment in renewable energy, particularly in solar and wind, will require ongoing advancements in efficiency, capacity, power density, and cost-effectiveness. Wolfspeed recently partnered with EPC, a leading utility-scale renewables inverter manufacturer, to enable a modular, two-level system architecture as shown in Fig. 4. This unique power design ultimately ensures a low maintenance, easily serviced, and mass producible inverter approach for rapid renewable deployment. For more information on how the previous three-level system was simplified with SiC, read more in Wolfspeed’s case study [4]

simplified 2-level system utilizing the 2300 V WolfPACK power module (right). The simplified 2-level system has a

reduced driver count and control complexity, along with improved scalability.

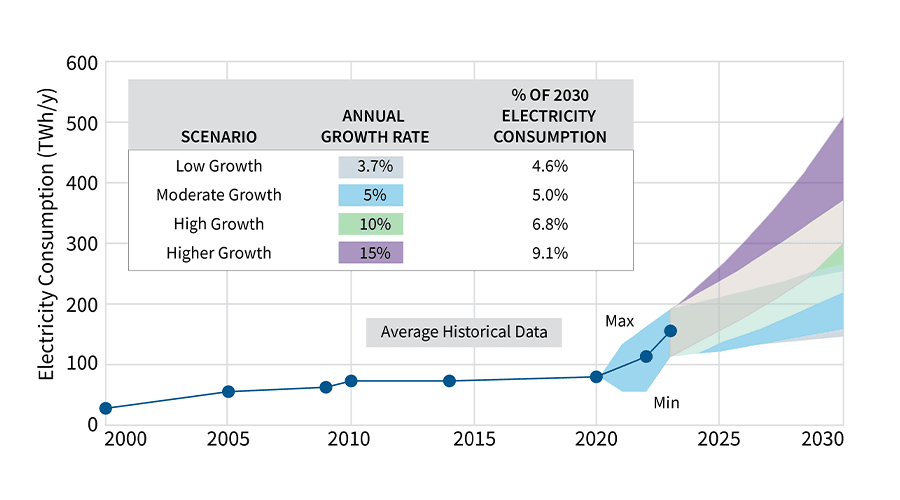

C. The AI revolution and Its Impact on Data Centers

Artificial intelligence (AI) is driving an unprecedented demand for data centers, significantly increasing global energy consumption. As shown in Fig. 5, in 2021 major tech companies like Amazon, Google, Meta, and Microsoft used 72 terawatt-hours of electricity, more than double their 2017 consumption, and this demand has only intensified with the rise of generative AI technologies such as ChatGPT. AI models are far more energy-intensive than traditional applications, with AI queries requiring around 2.9 watt-hours per request—nearly ten times the energy needed for a typical Google search.

The 2024 ERPI report predicts that data centers could consume up to 9.1% of U.S. electricity by 2030, making it critical to find sustainable solutions for AI workloads [5]. While some companies experiment with cooling methods like submerging servers in oceans or using snow, SiC technology presents a more practical, cost-efficient solution. SiC devices generate less heat and keep reliable performance in high-temperature environments, improving energy efficiency and reducing the need for external cooling.

SiC’s superior power density—due to its better figure of merit and thermal conductivity—allows for either a 40% increase in power or a 40% reduction in system size. If all data centers globally replaced silicon-based components with SiC, the energy savings could power Manhattan for an entire year. Over the past decade, global regulations have increasingly demanded higher external power supply efficiency, and SiC and GaN are the only materials capable of meeting the strictest standards, such as 80+ Titanium, ORV3, and Energy Star efficiency standards, at the lowest system cost. Incorporating SiC not only enhances energy efficiency but also ensures that data centers can meet evolving regulatory requirements while minimizing environmental impact, reducing operational costs, and maximizing computing capabilities.

IV. Silicon Carbide Technology Maturity

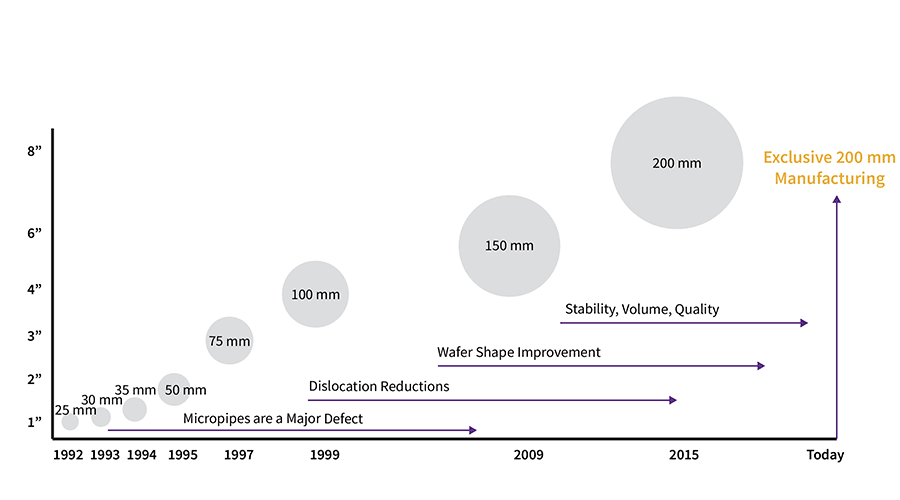

As SiC devices gain traction in advanced applications, there is a growing need for low-defect, high-quality SiC materials. These high-quality substrates and wafers are crucial for achieving best device performance and reliability, as defects like micropipes and dislocations can significantly reduce both efficiency and lifespan, particularly in high-voltage systems. As reflected in Fig. 6, Wolfspeed continually enhances production processes to produce higher quality, larger diameter and more consistent SiC crystals, improving both reliability and efficiency. Over the past few decades, SiC technology has evolved from experimental stages to widespread commercial use, overcoming early challenges in manufacturing consistency and cost.

The foundation for SiC research was laid by the work of Tairov and Tsvetkov in 1978 [6], which set the stage for future advancements. In 1987, Cree Inc. (now Wolfspeed), a pioneer in SiC technology, was founded, and by 1992, the company produced the first commercial SiC substrate, marking a significant technological leap. A breakthrough came with the introduction of Zero Micropipe (ZMP) substrates, addressing the issue of micropipes which is a critical device killing defect in SiC materials. The transition from smaller wafer sizes, starting with 1-inch wafers in 1992, to larger sizes of 200mm wafers in 2015, was instrumental in improving manufacturing efficiency and reducing costs.

Alongside these diameter increases, Wolfspeed made significant improvements in the quality of SiC substrates by reducing dislocation density and enhancing wafer shape, leading to higher yielding and more reliable SiC devices. As Wolfspeed continues to mature its 200mm SiC technology, it underscores the importance of achieving stability, high-volume production, and consistent quality in SiC materials and devices, as shown in Fig. 7. These advances have matured the SiC technology on a global scale, enabling its application in the sophisticated systems outlined above.

VI. Future Trends with Silicon Carbide Technology

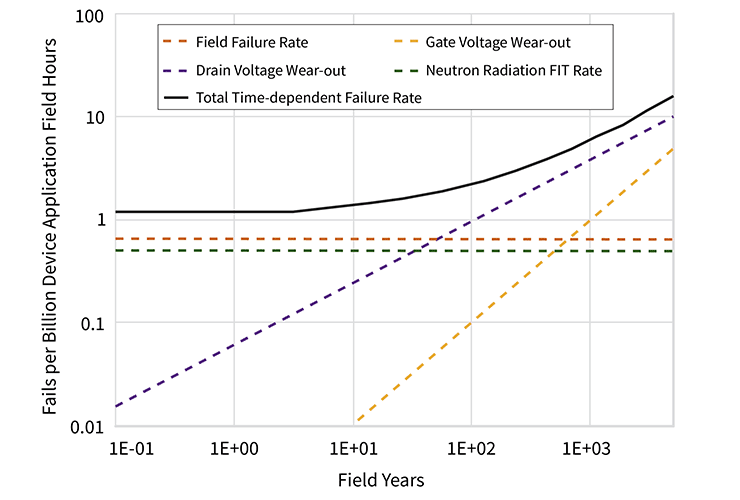

The future of power electronics is being shaped by ongoing innovations in SiC technology, with trends going beyond traditional reliability concerns to a greater focus on durability, efficiency, and advanced integration. As more industrial and renewable energy applications push to operate off-of higher bus voltages, wide bandgap (WBG) technologies must contend with the challenging environments that many of these applications are installed in. As power component suppliers are evaluating the critical measures for best performance in high-voltage, high-frequency applications, it becomes essential to think beyond the datasheet for key reliability criteria and consider what enhancements or even specifications are important to ensure greater durability.

For example, for high-altitude applications, degradation due to cosmic ray particles must be considered, as it has a tangible impact on failure-in-time (FIT) rates. For renewable energy installations, performance in humid environments may be of concern so temperature humidity bias (THB) specifications could be a requirement. And as construction and agriculture vehicles (CAV) become increasingly electrified (Fig. 8), understanding the gate oxide stress is important as the devices in CAVs must withstand elevated temperatures due to their use condition. This last requirement also highlights the ongoing technological development for SiC devices to unlock future potential [7].

The onus is on WBG component suppliers to understand the increasing challenges that come with designing for durability, and carefully navigate the design tradeoffs that are needed to achieve the appropriate performance, while ensuring that SiC is still commercially acceptable to reliable, long-standing IGBT-based systems. Beyond device design and processing innovations, advanced packaging technologies will also be crucial to fully exploit the benefits of SiC by addressing thermal, electrical, and mechanical challenges that are common in harsh environments.

Another visible trend in power electronics is the shift from individual power converters to more integrated systems, with a greater emphasis on holistic energy management rather than isolated power functions. This transition involves analyzing the interactions between various system components to refine not just power, but overall energy efficiency. This shift also reflects the continuous evolution of power converter technology, driven by breakthroughs in semiconductor devices like SiC, new circuit topologies, innovative control strategies, and seamless system integration. The trend towards higher efficiency, greater power density, and more integrated solutions will likely dominate the power electronics landscape in the coming years.

Conclusion

The transition from silicon to SiC is a once-in-a-generation technological shift in the field of power electronics. SiC offers superior material properties compared to traditional silicon, such as higher thermal conductivity, greater breakdown voltages, and faster switching speeds, which make it ideal for high-power, high-temperature, and high-efficiency applications. As Wolfspeed pushes the envelope of SiC technology advancements and delivers high quality SiC products consistently at high volumes, this shift becomes not just an incremental improvement but a foundational change that is enabling new levels of performance across a wide range of industries. By leveraging SiC technologies, industries are able to achieve significant advancements in performance, all while reducing operational costs and carbon emissions. The increased adoption of SiC marks a pivotal moment in power electronics and semiconductors overall as it opens possibilities that were previously unattainable with silicon, shaping the future of energy management and power conversion technologies for decades to come.

References

- Lorenz L., Erlbacher T., Hilt O., Future technology trends, Wide Bandgap Power Semiconductor Packaging: Materials, Components, and Reliability, pp. 3-53. 2018

- McKinsey & Company, “Managing uncertainty in the silicon carbide wafer market,” Aug. 2024

- Semiconductor Today. Silicon carbide substrate costs falling as larger diameters adopted. Published March 2024.

- International Energy Agency (IEA), “Renewables 2023,” License; CC BY 4.0, Apr. 2024

- S. Magargee, “Keeping the lights on with Wolfspeed SiC,” Aug. 2024

- ERPI, “Powering Intelligence: Analyzing Artificial Intelligence and Data Center Energy Consumption,” May 2024.

- Yu. M. Tairov, V.F Tsvetkov “Investigation of growth processes of ingots of silicon carbide single crystals,” Journal of Crystal Growth, March 1978

- [8] Wheri Z., Godbold V., Schlegel M., Hudgins J.L. “Oxide Failures in SiC Power MOSFETs,” IEEE, Oct. 2023