SiC Boosts Double-Conversion UPS Efficiency, Power Density

Article

For most enterprises today, smooth operation of data centers is the lifeline of business. Increasing cloud computing and virtualization are helping grow server facilities that consume over 2% of the world’s electrical energy. In the U.S. alone, data centers consume 90 TWh of electricity that can keep about 30 big coal-fired power plants fully utilized.1

This scale of power consumption has prompted governments to consider regulations to control power factor (PF) and efficiency. For instance, the EU data center code of conduct encourages participants to reduce energy consumption in a cost-effective manner.2

Designing a UPS solution that is reliable, efficient, and cost-effective is a key consideration for commercial setups like data centers, where typically a double-conversion system is used to provide constant voltage and constant frequency 24 hours a day, seven days a week.

What is a double-conversion UPS?

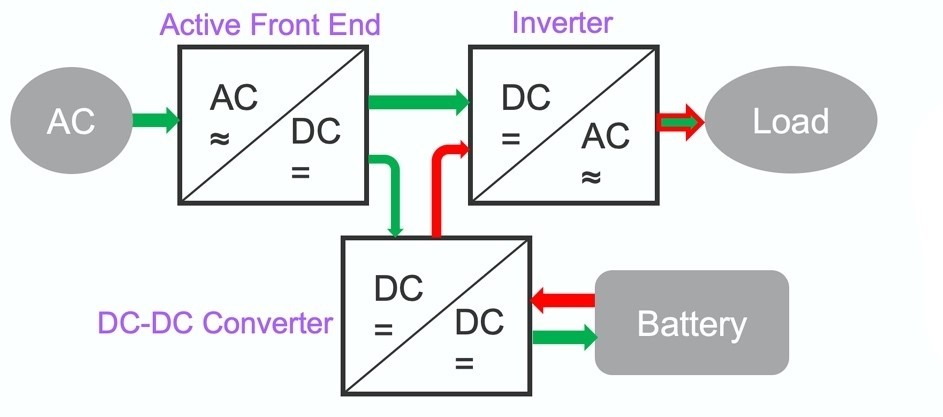

The double-conversion UPS architecture comprises an active front end (AFE) or rectifier, a DC/DC converter, and an inverter (Figure 1). In normal power flow, a small current goes into the DC/DC converter that maintains the battery charge. Most of the power is sent through the DC link into the inverter where it feeds the load. This gives the topology its name, as the rectifier drives the inverter even when powered from the AC grid.

Under a power fault, the AFE stops switching and the DC/DC converter sends power from the battery into the inverter to feed the load. The energy stored in the battery can also be used to compensate for poor load and grid-side power quality.

The AFE and the inverter have similar configurations, each using three half-bridge converters—one for each phase. Whereas the AFE regulates current, the inverter regulates both current and voltage on the AC output. The bidirectional DC/DC converter comprises two half-bridge power modules that boost to the battery and buck from the battery to the DC link.

SiC vs. IGBT in UPS design

There is a choice of component technologies available today for designing a typical 200-kW double-conversion UPS system. While silicon insulated gate bipolar transistors (IGBTs) have been used in such systems, silicon carbide (SiC) trumps silicon in high-voltage power solutions in terms of efficiency, power density, and cost effectiveness.3

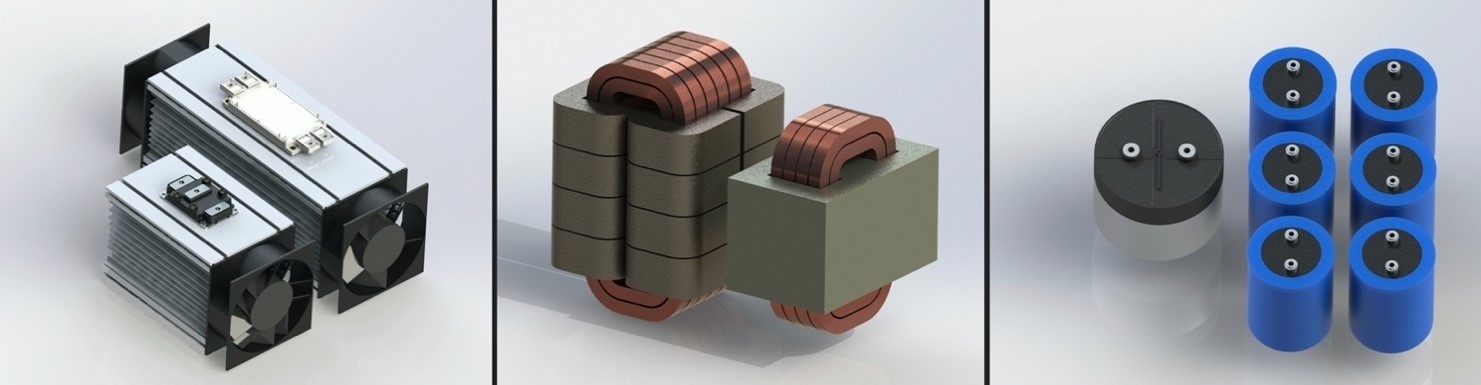

A best-in-class silicon IGBT-based design (Figure 2) uses power modules switching at 8 kHz to maximize the tradeoff between system size and system losses. The modules need a heat sink and pusher and puller fans to generate enough airflow for managing system heat.

The losses per module in the AFE run up to 1.1 kW, with IGBTs and diode junction temperatures (Tj) reaching 130°C and 140°C, respectively, at a case temperature (Tc) of 40°C. The design requires 6.4 L of heat-sink-and-fan volume to dissipate that much power.

For the DC/DC converter, the losses are about 590 W per module. While diode Tj is lower at 75°C, the IGBT Tj rises to 136°C. The DC/DC converter not only needs 3 L of heat-sink-and-fan but 1.9 L of a 100-μH inductor using up 182 W as well as 3.6 L of 2.32 mF in electrolytic capacitors.

SiC power modules can be used in the same topology (Figure 3) and, with some optimization, take the switching frequency to 25 kHz and deliver compelling benefits:

- The SiC-based AFE losses per module come down to a mere 662 W.

- Rated as high as 175°C, the SiC modules can run hotter and reach a Tj of 164°C @ Tc 40°C.

- Because the SiC MOSFET integrates a body diode, the modules do not require additional diodes and are therefore smaller.

- With the modules running hotter and system losses significantly lower, a smaller heat sink with only one fan is required for heat management. This takes down the cooling system volume for each module to 3.7 L.

A major benefit of using SiC in a DC/DC converter is the capability of using synchronous switching, where most IGBTs are at a disadvantage, as they cannot conduct in the third quadrant. SiC, instead of using a diode, uses the MOSFET channel in the reverse direction and decreases conduction losses in the system. The converter therefore offers the following benefits

- A much lower single-module power loss of 284 W

- An allowable higher MOSFET Tj of 143°C @ Tc 40°C

- Cooling system volume of just 1.9 L

- Dramatic reduction in inductor requirement to 1.2 L of 30 μH consuming 137 W

- Higher frequency that translates to significant savings in capacitance at 1.2 L of 740 μF in film capacitors that also help increase system reliability/lifetime over electrolytic capacitors

Advantages of SiC

A component-by-component comparison (Figure 3) of the IGBT- and Wolfspeed XM3 module-based double-conversion UPS shows a clear advantage from the SiC system:

- 40% reduction in losses, 42% reduction in cooling volume, and 43% reduction in thermal solution cost

- 37% reduction in inductor size, 20% lower losses in the inductor, and 23% less inductor cost

- 67% reduction in capacitor volume and 66% lower capacitor cost

System-level gains from SiC

Apart from maximizing efficiency, a UPS must provide an energy storage buffer to withstand power outages and other issues, including surges and brownouts, minimize power quality issues by sourcing very low THD current with high PF, minimize component costs, and shrink system volume to save high-rent space or make room for additional batteries.

The advantage in volume, losses, and cost due to Wolfspeed’s XM3 power module means that the 200-kW SiC-based system would result in 35% savings in bill-of-materials (BoM) cost for passives and 38% savings in losses that translate to an annual reduction of 26 MWh or $2,591 at $0.10 per kilowatt-hour.

This advantage extends to power quality as well. A SiC vs. IGBT comparison via system simulation (Figure 4) reveals that silicon’s lower switching frequency (8 kHz) limits its response to the change in load, taking 16.4 ms to settle. The SiC-based system’s 3× higher frequency allows it to reject the load 3× faster—in 4.9 ms.

This level of performance is available for evaluation with Wolfspeed’s three-phase inverter reference design, the CRD250DA12E-XM3, that offers 250-kW peak output power, a 900-V DC bus (max), and 300-ARMS phase current (max) from a compact and lightweight 9.3 L and 6.2 kg. Contact Wolfspeed to find out more.

References

- Global Market Insights, Data Center UPS Market report for 2020–2026, (https://www.gminsights.com/industry-analysis/data-center-UPS-market)

- Code of Conduct for Energy Efficiency in Data Centres, (https://joint-research-centre.ec.europa.eu/energy-efficiency/energy-efficiency-products/code-conduct-ict/code-conduct-energy-efficiency-data-centres_en)

- Silicon Carbide Enables PFC Evolution,(https://www.arrow.com/en/research-and-events/articles/silicon-carbide-enables-pfc-evolution)