Silicon Carbide Pulls Green Alternatives into Virtuous Cycle

Article

The green consciousness and regulations driving the EV market have fueled innovation in battery technology and Silicon Carbide-based design to transform green energy generation.

The need for renewable energy expansion is now critical. Increasing climate variability, near-term fossil fuel supply chain problems as well as long-term limited fossil fuel resources facing an ever-growing energy demand have tipped the scales in favor of regional green energy sources.

Significantly increasing the return on investment (ROI) in renewable energy, particularly solar and wind, means increasing efficiency, capacity, power density, and cost effectiveness of energy storage systems (ESS). And solutions are now available to help achieve all those goals thanks to the innovations in battery technology and Silicon Carbide devices accelerated by the growing electric vehicle (EV) market.

Sun shines on solar success

The International Energy Agency (IEA) estimates renewable capacity will increase by 8% to cross 300 GW in 2022.1 Leading the renewable renaissance, according to the agency, is solar PV, which will account for 60% of this growth in global renewable capacity. Behind this growth are several reasons, including the progressive resolution of some of the challenges.

- Solar panels and associated electronics have become more efficient, while also achieving lower cost relative to fossil fuels — and at a faster pace than wind and hydro. Governments globally are building on this through commercial incentives and regulatory support.

- The characteristic intermittence of energy generation from wind and solar, worsened by climate variability2, can be mitigated with the addition of ESS. Improvements in battery technology are offering capacity expansion and lower costs, while Silicon Carbide based design is making these systems more efficient.

- A key advantage of solar PV is its broad scalability from a few kilowatts in residential applications to megawatts in utility-scale solar farms. Unlike wind and hydro that are most viable at very high power and expensive utility-scale investments, solar fits a diverse set of system configurations.

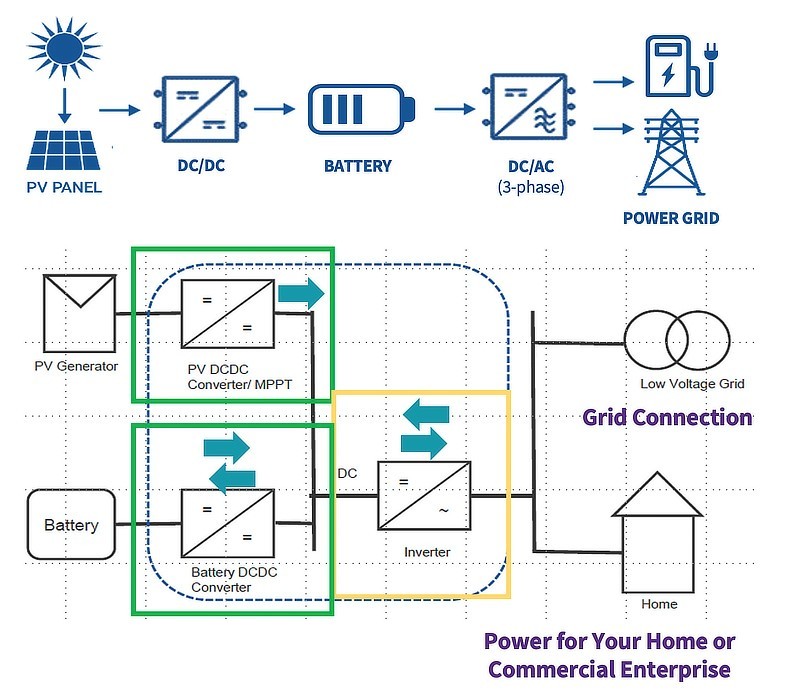

Panel to ESS system overview

Solar architectures generally split into three configurations. At the residential level, microinverters support 1-4 panel blocks. String inverters aggregate panel clusters from a few kilowatts to about 50 kW. From 50 kW to 200 kW, strings are integrated to serve commercial and industrial installations. Utility-scale installations in the megawatts range have used large centralized systems but are now often choosing distributed string-based topologies to lower installation time and cost as well as impact of point failures and overall maintenance cost.

The maximum power point tracker (MPPT), which is a DC-DC boost circuit, takes the varying voltage from the panel array and offers a constant higher voltage to the internal bus (Figure 1). The more stable DC is then converted to grid-standard AC by the inverter. In ESS implementations, a bi-directional DC-DC buck-boost circuit acts as battery charger. Should the ESS need to be charged from the grid, the inverter also needs to be bidirectional.

Silicon Carbide technology boost

Silicon Carbide fits this application right from low 1-kW to greater than 1-MW configurations in the boost/MPPT DC-DC, the bidirectional inverter or active front end (AFE), and the bidirectional DC-DC in the ESS charging/discharging circuit. And it offers numerous advantages over Silicon:

- 3X higher switching frequency in most applications

- ~2% increase in system efficiency or ~40% lower losses

- Up to 50% higher power density (3X smaller, 10X lighter)

- Smaller passives and heatsinks

- Lower total system BOM costs

Although Silicon Carbide Schottky diodes have long been used in the MPPT boost circuit to increase efficiency, there is now broader adoption of full Silicon Carbide implementations with MOSFETs. For instance, Wolfspeed’s CRD-60DD12N 15-kW-by-4-channel boost converter reference design offers 99.5% energy efficiency and switching at 78 kHz. Compared to what is achievable with Silicon, this design delivers 1-2% higher energy efficiency or about 70% reduction in losses, 3X power density, and 10X reduction in weight. All that performance at a lower system implementation cost.

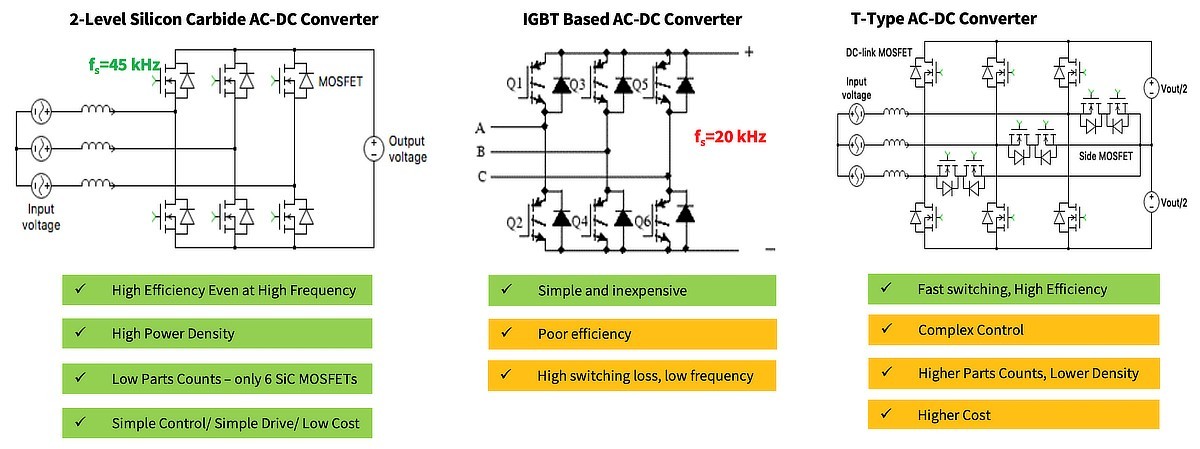

Silicon Carbide has a similar impact on the AFE section. A six-switch Silicon IGBT implementation is commonly used for its relatively low cost and simplicity (Figure 2). However, its switching frequency is limited to a maximum of about 20 kHz and, at high power levels, significantly lower than that. Multi-level topologies using Silicon Super Junction (SJ) devices allow designers to achieve the high voltage levels needed with high frequency switching and good system efficiency but only at the expense of complex control and a significantly higher part count and BOM cost driven by additional switches as well as associated device drivers. This has been demonstrated by Wolfspeed’s CRD25AD12N-FMC 22 kW AFE reference design.

In the ESS space, the EV market has influenced the battery storage trend enabling use of battery packs from 200V and potentially moving toward 800-1000 V. These high voltages require high-voltage devices in the bidirectional DC-DC converter. Designers have often used common 650 V SJ devices in complex, multi-level resonant topologies where Silicon has limited switching to between 80 kHz and 120 kHz. Instead, simpler full Silicon Carbide implementations, such as the CRD-22DD12N 22-kW bidirectional DC-DC charger, can achieve resonant frequencies of about 200 kHz with lower part count and overall system cost.

Combining the Silicon Carbide based bidirectional AFE and DC-DC charger results in several system-level advantages:

- 40% lower energy losses that in turn enable

- 2% improvement in system-level efficiency

- 50% better power density

- Up to 18% lower system cost

Future built with high-power Silicon Carbide

Several key, near-term trends are supported by Silicon Carbide-based systems. The solar world is moving toward a 1500 V bus, which requires 2 kV devices or a complicated multi-level topology. In the central inverter area, mid-to-high-voltage devices and power modules in the 2 kV or higher range will be required.

Silicon Carbide will deliver a unipolar switch as opposed to the bipolar switches in today’s central inverters, bringing the same efficiency, weight, size, and cost advantages. The new technology will also impact new segments, including solid-state transformers, wind power, and traction.

While there is a great variety of Silicon Carbide discrete devices and power modules available to cover current needs, Wolfspeed continues its tradition of investing in R&D to bring new products to market to meet these future requirements. Visit www.wolfspeed.com/applications/power/renewable-energy/ to learn more.

References

- IEA, Renewable Energy Market Update - May 2022 (https://www.iea.org/reports/renewable-energy-market-update-may-2022)

- euronews.green, Powering up wind energy in a world of climate variability (https://www.euronews.com/green/2022/05/25/powering-up-wind-energy-in-a-world-of-climate-variability)